Chemical Cleaning, Degreasing and Rinsing

Chemical cleaning can be part of a manufacturing procedure to prepare products for the next process in line or as part of a final treatment for functional use. Cleaning processes may remove unwanted stains, contamination, surface or trapped chemicals or remove dust and debris. Determination of the nature of contaminants on a physical and chemical level as well as understanding the substrate materials chemistry is vital to determination of a reliable and effective chemical cleaning process. LPD Lab Services provides both characterisation of contamination and practical advice for effective cleaning solutions and methodology.

Chemical cleaning can be part of a manufacturing procedure to prepare products for the next process in line or as part of a final treatment for functional use. Cleaning processes may remove unwanted stains, contamination, surface or trapped chemicals or remove dust and debris. Determination of the nature of contaminants on a physical and chemical level as well as understanding the substrate materials chemistry is vital to determination of a reliable and effective chemical cleaning process. LPD Lab Services provides both characterisation of contamination and practical advice for effective cleaning solutions and methodology.

The laboratory has extensive experience in diagnosing and eliminating product and process contamination including cleaning, degreasing and subsequent rinse processes. It also offers practical recommendations of alternative methods.

- Alternative cleaning processes.

- Tuning process recipes.

- Improved working practices.

- Process control methods.

- Site visits and technical sanity audits from experienced product cleaning expert.

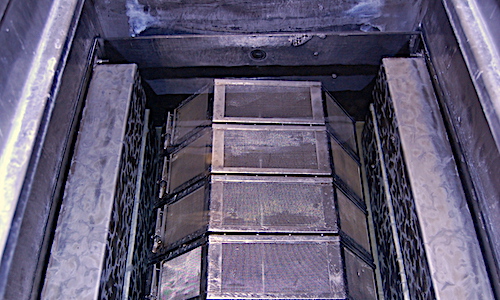

Surface Analysis techniques in particular are ideal for tuning of cleaning and rinsing processes with their surface chemical sensitivity. Bath rinsing practices are critical as use of town water, insufficient rinse times or poor refreshing practices optimising against process product throughput. Poor practices can leave unwanted staining and contamination.

We have an ideal range of surface analysis techniques that can help identify cleaning, degreasing and rinsing issues. These include: XPS, SIMS and AES / SAM coupled with SEM / EDX, GC-MS and FTIR.

Tighter environmental and Health and Safety regulations mean that many industries are required to replace solvent based cleaning / degreasing processes with aqueous-based systems. Although aqueous degreasers are safer for operators, they tend not to be as effective: They leave remnants on the material surfaces, potentially affecting a component’s fitness for use or downstream manufacturing. The lab has extensive experience in the change over of solvent based cleaning / degreasing processes to aqueous and also of the problems this can lead to. We can work to isolate / identify contamination levels and offer elimination advice with optimised cleaning agent formulation, depending on our findings.

Typical Cleaning and Rinsing Process Improvement Applications:-

Typical Cleaning and Rinsing Process Improvement Applications:-

- Optimisation of aqueous degreasing and rinsing to replace a solvent cleaning process.

- Effectiveness of an aqueous degreasing process evaluated and improved by XPS.

- Degreasing process optimisation prior to painting.

- SEM of microscopic roughness to investigate difficulties in product cleaning due to trapped volumes.

- Identification and elimination of unknown stains on fabrics, materials and manufactured components by XPS, FTIR, GC-MS and SEM.

- Root cause analysis of metal surface discolouration by SIMS, XPS and SEM / EDX.

- Weak boundary layer determination in adhesive and coating problems.

- Fine tuning of cleaning, degreasing and final rinsing processes to remove stains.

- Contamination on circuit board soldering joints.

- Failing paint coatings on car bodies and car sub-components.

- Delamination of metallic coatings on test equipment.

- Adhesive and sealant failure investigations and formulation improvement.

- Process dust and particle contamination elimination