Chemical Product Deformulation and Reformulation

LPD Lab Services can help in deformulation and reformulation of products. This may involve many of the varied types of investigation available for example :

- Physical analysis

- Microscopy and SEM/EDX

- Surface analysis

- Chemical analysis

- Classic chemical analysis.

Chemical analysis is divided into two major categories:

- Proximate analysis such as loss on drying which measures a bulk property such as moisture.

- Compositional analysis such as the identity or quantity of a substance or both in the formulation being investigated.

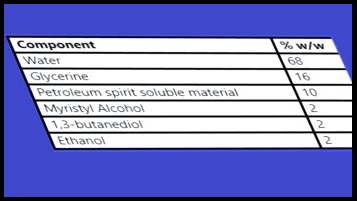

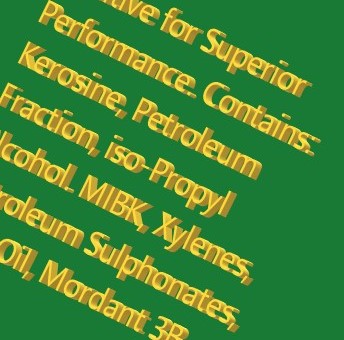

Deformulation is the process of taking a formulated chemical or material product separating and identifying its constituent components, identifying and quantifying each component so that the end result is a recipe for the product.

Deformulation is the process of taking a formulated chemical or material product separating and identifying its constituent components, identifying and quantifying each component so that the end result is a recipe for the product.

Organisations can have many reasons for deformulating products such as checking a product for banned substances, confirmation of product identity, benchmarking, defending a patent or even competitor product reverse engineering.

The methods used to deformulate a product are varied and depend upon the type of product product as well as the available budget. At LPD Lab Services we have access to a wide variety of analytical techniques to separate and identify the components and are able to advise on the approach that is most likely to yield a result within the available budget..

Our aim at LPD Lab Services is not only to provide the customer with a breakdown of contents of a product but also to provide a value added service, for example we can:

- Make trial batches of the product if necessary (generally up to 100 litres) and / or advise the customer how to make it themselves safely and accurately.

- Give guidance on improving or altering the formulation to differentiate it from existing products or to give additional functionality.

- Advise on replacements and alternatives where a formulation contains banned or environmentally problematic substances.

Please contact us to confidentially discuss your requirements with our staff and find out how LPD Lab Services can help you

No documents matching criteria