SIMS (Secondary Ion Mass Spectrometry)

Principle of SIMS (Secondary Ion Mass Spectrometry)

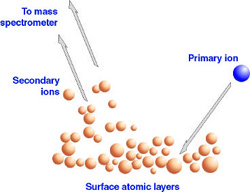

SIMS uses charged primary ions focused at a sample to sputter off atoms and molecules characteristic of the outermost atomic layers of the material. The primary ion dose can be carefully controlled so that the damage to the surface is negligible and the technique is essentially considered as non-destructive (so called static SIMS). Larger numbers of ions per unit area can also be used to sputter into the bulk of the sample (so called dynamic SIMS). This mode of operation allows chemical depth profiles to be obtained.

SIMS uses charged primary ions focused at a sample to sputter off atoms and molecules characteristic of the outermost atomic layers of the material. The primary ion dose can be carefully controlled so that the damage to the surface is negligible and the technique is essentially considered as non-destructive (so called static SIMS). Larger numbers of ions per unit area can also be used to sputter into the bulk of the sample (so called dynamic SIMS). This mode of operation allows chemical depth profiles to be obtained.

In the SIMS process in our instrument primary gallium ions knock out secondary ions and molecules from the surface atomic layers. These secondary ions are detected as a mass-to-charge ratio by the quadrupole mass spectrometer. As well as secondary ions, this sputtering process generates large numbers electrons, which can be used to produce a physical image of the sample surface similar to that obtained in an SEM.

In non-conducting samples the sputtering process causes the sample to charge, which can severely affect the sensitivity of the analytical technique. To eliminate this problem the MiniSIMS instrument is fitted with a charge compensation gun, which indirectly floods the sample with low energy electrons.

In non-conducting samples the sputtering process causes the sample to charge, which can severely affect the sensitivity of the analytical technique. To eliminate this problem the MiniSIMS instrument is fitted with a charge compensation gun, which indirectly floods the sample with low energy electrons.

SIMS spectra can be acquired in a point and shoot manner. Multiple static points, small areas and large areas can be scanned from chemical or physical (SEM) images highlighting the areas of interest. These typically only take 30s to acquire. Chemical and molecular maps can also be rapidly (about 30s each) acquired to determine local inhomogeneities in surface chemistry.

The use of SIMS with XPS is a powerful combination of techniques for the identification of surface distributions of elemental and molecular species, optimised sensitivity coupled with chemical state quantification: Issues of surface and interface contaminants and compounds are often best addressed with both the two methods, providing a faster and more comprehensive materials characterisation.

Information Available from SIMS

SIMS can provide us with the following information:

- Small and large area SIMS

- Chemical imaging

- SED imaging

- Elemental depth profiling. (sub- surface down to 100nm)

- Can detect all elements and also isotopes of the same element

- Relative quantification

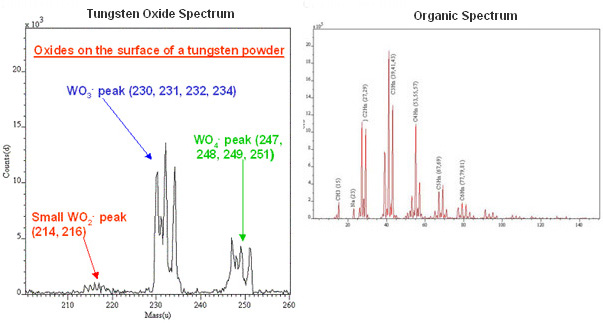

- Molecular cluster information

- Small feature surface chemical analysis

Example Range of Materials and Samples for SIMS

- PCBs, electronic components and devices

- Semiconductors

- Metal

- Plastics / Polymers

- Ceramics

- Organics and Inorganics

- Catalysts

- Surface and interface contaminants

- Biological Samples

- Thin Films

Our site expert on SIMS is Dr Stephen Jenkins.

Application Notes