Composite Release Films and Mould Release Agents

There are cases in materials manufacture and use where poor adhesion between dissimilar materials is an advantage rather than a drawback. PTFE non-stick coatings on frying pans is a typical example where weak adhesion is a distinct advantage coupled with the relatively high temperature resistance of the polymer.

Mould release can be aided by materials additions or intermediate release films:-

Mould Release Films in Composites Materials

Mould Release Films in Composites Materials

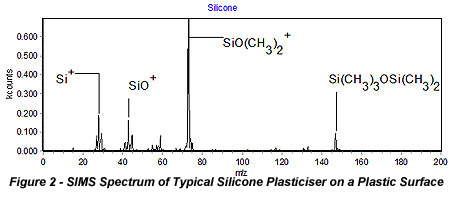

During lay up and autoclaving of carbon fibre reinforced composites CFRP the use of ETFE and similar polymer blends as mould release films is common place. The surface concentration of the fluorine is critical in these films. Sufficient fluorine species must be present at the film surface to affect complete release after the autoclave process. However, too much surface fluorine can give too little tack between film and substrate and interfere with effective laminate lay up. Conversely, poor release characteristics can lead to the release film failing cohesively rather than adhesively and remnant film on the composite surface. Removing the excess material can damage the structure of the composite product affecting process yield. In addition, fine fragments can remain undetected on the surface. Remnant release films have led to catastrophic interlaminate layer failure in aircraft as the weak boundary layer, where material has been left behind, acts as a crack initiation point between plys. This gives a stress concentration and crack growth under the typical fatigue loading seen in operational service of civil and military aircraft.

Remnant release films can be so thin that they can only be detected by surface analysis techniques. FTIR can be used to rapidly check the bulk composition of the release film polymer blends to insure the correct material is being used or control batch to batch variations. Surface segregation of the active fluorine containing part of the blend can be checked by XPS or SIMS.

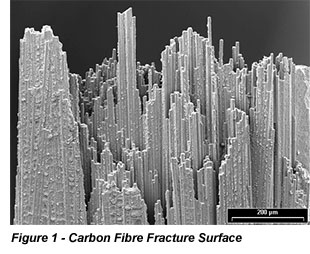

Mould Release Agents

Mould release agents are often used in the manufacture of plastic products, particularly in volume manufacturing. They are added to the polymer formulation or periodically applied to the inside of the die in injection moulding and vacuum forming to reduce the chance of the product sticking and ease ejection. Ultimately their use affects the process throughput. Too much release agent or plasticisers used to aid mould flow characteristics can interfere with the adherence of paints and glues. Surface analysis techniques XPS and SIMS are ideal for identifying their presence and tuning the amounts used in a process. FTIR and GCMS also can be used to identify the plasticiser and release agents used.