XPS - X-ray Photoelectron Spectroscopy

Principle of XPS

XPS (X-ray Photoelectron Spectroscopy) or ESCA uses a soft X-ray source (AlKα or MgKα) to ionise electrons from the surface of a solid sample. The binding energy of these electrons are measured and are characteristic of the elements and associated chemical bonds (chemical state) in the top few atomic layers of the material.

XPS (X-ray Photoelectron Spectroscopy) or ESCA uses a soft X-ray source (AlKα or MgKα) to ionise electrons from the surface of a solid sample. The binding energy of these electrons are measured and are characteristic of the elements and associated chemical bonds (chemical state) in the top few atomic layers of the material.

Samples can be tilted to affect the escape depth of the electrons and thus determine the depths of overlayers on a surface. This non-destructive depth profiling, known as angle resolved XPS, also allows surface bond orientation to be explored particularly relevent for adhesion and joining technology and wetting issues.

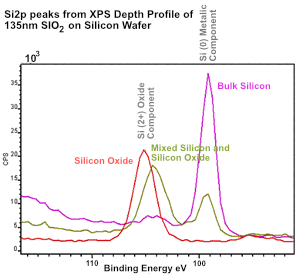

For analysis beyond the top 1-5nm an inert gas ion gun (normally Argon) can be used to sputter off the surface layers before analysis. Alternating sputtering and XPS spectral acquisition permits chemical depth profiles to be obtained.

Information from XPS

XPS is a quantitive spectroscopic technique which analyses the average surface chemistry of a sample up to a depth of approximately 3-5nm. This technique quantitatively measures the elemental composition, atomic concentrations and chemical states of elements present at a samples surface. XPS can detect all elements with an atomic number greater than 3, therefore, Hydrogen and Helium are not possible to detect. The area of analysis is typically 10mm2 but small areas down to 150μm x 150μm are possible.

Example Range of Materials

Example Range of Materials

- Metal Alloys

- Glass

- Ceramic materials

- Polymers and Plastics

- Paint / Coatings

- Paper and Coatings

- Biomaterials and Implants

- Medical Devices

- Inks

- Oil Layers

- Contaminant identification

- Wood

- Plants

- Semiconductors

- Composite Materials

- Inorganic & Organic Compounds

- Glues/ Adhesives

- Surface Contaminants

- Interfacial Chemistry

- Catalyst Materials

- Corrosion Products and Corrosion Inhibitors

Example Typical Applications

- CRT (cathode ray tube) cathode heater coating improvement for improved heat transfer and cross-production tool process matching.

- Metal component thermal oxidation or reduction process effectiveness (growth or removal of oxide or surface segregating materials)

- Surface Ni/Cr ratio in a nickel chromium alloy affecting catalytic gas cracking activity

- Checking for weak boundary organic layers affecting paint or adhesive adhesion

- Improvement of chemical cleaning or etching processes

- Identification of unknown contaminants such as surface films and pipe blockages

- Surface oxide thicknesses in semiconductor processes - depth profiling

- Sputtered layer process chemical characterisation and depth profiling

- Stress Corrosion Cracking Analysis (SCC) of Brass and Copper

- Paint and Coating wetting problems coupled to contact angle measurements

- Wetting and adhesion optimisation on printing inks and adhesion.

Our site expert on XPS is Dr Stephen Jenkins.

Application Notes