Scanning Electron Microscopy SEM / EDX Analysis

Scanning Electron Microscopy (SEM) has many applications across a multitude of industry sectors. It can produce  extremely high magnification images (up to 200000x) at high resolution up to 2nm combined with the ability to generate localised chemical information (EDX). This means the SEM / EDX instrument is a powerful and flexible tool for solving a wide range of product and processing problems for a diverse range of metals and materials.

extremely high magnification images (up to 200000x) at high resolution up to 2nm combined with the ability to generate localised chemical information (EDX). This means the SEM / EDX instrument is a powerful and flexible tool for solving a wide range of product and processing problems for a diverse range of metals and materials.

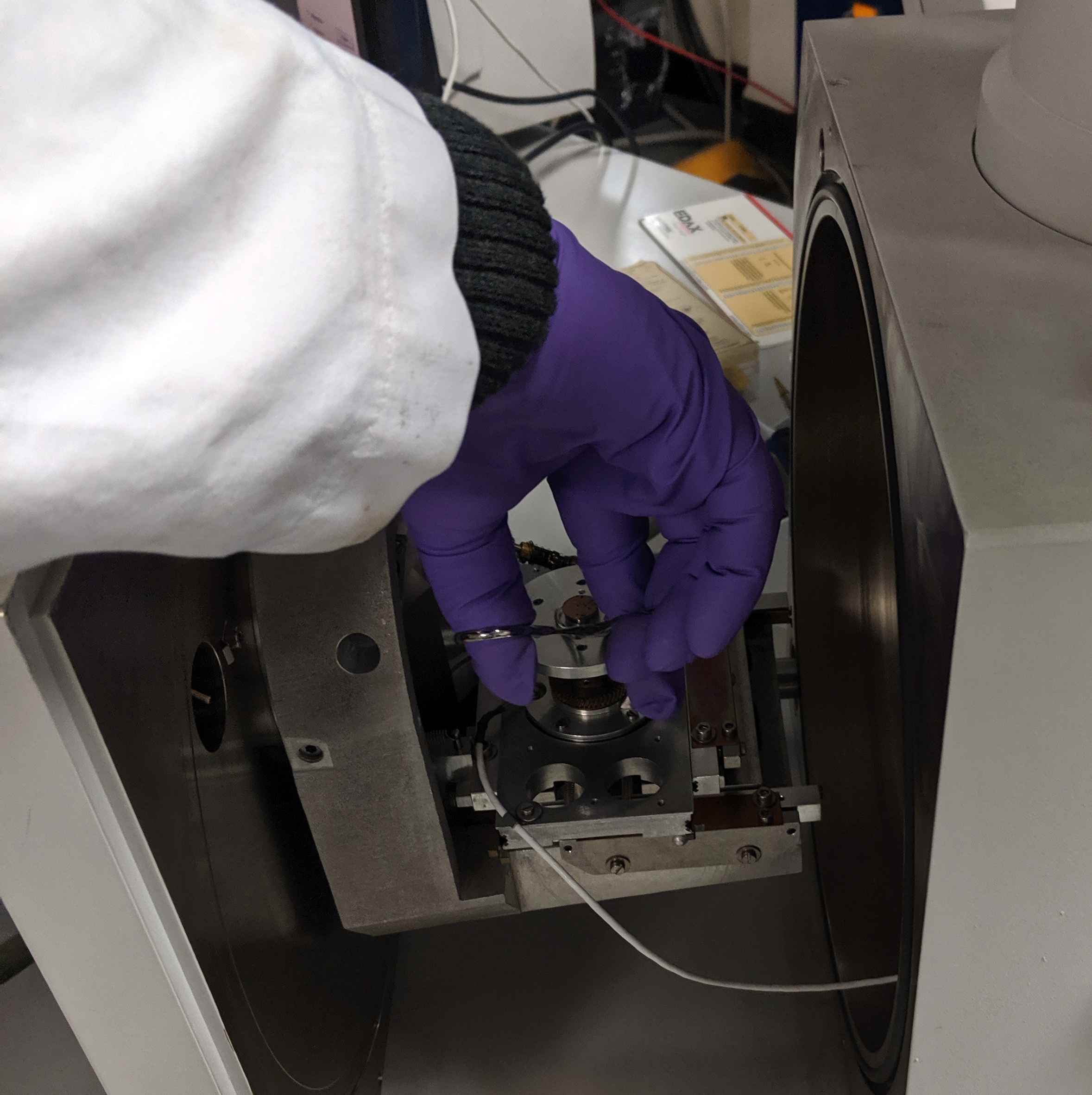

LPD Lab Services has 2 SEM instruments and has extensive experience in using SEM / EDX analysis in many industrial sectors;

electronics and semiconductors,pharmaceutical, petrochemicals, plastics and polymers, aerospace,automotive, medical devices, engineering, chemicals, materials and metallurgy.

Typical SEM Applications include:-

- Identification of metals and materials

- Particle contamination identification and elimination

- Classification of materials

- Product and process failure and defect analysis

- Examination of surface texture (including stereo imaging)

- SEM / EDX automated particle physical shape and size characterisation and EDX analysis

- Analysis and identification of surface and airborne contamination

- Powder morphology, particle size and analysis

- Cleaning problems staining and chemical etching

- Welding and joining technology quality evaluation and failure investigation

- Paint and coating failure and delamination investigation

- Paint, Adhesive, Sealant and Gasket Filler Fingerprinting

- Identification and elimination of corrosion and oxidisation problems

- Contamination or surface stain investigation

- Structural analysis and microstructural analysis

- Reverse engineering of products and processes

- Braking system fault diagnosis

- Hazard investigation of exfoliants from manufacturing process

- Source of fouling material in returned product.

- General hazard assessment of dust from storage areas

- Physical failure analysis of domestic water heaters and boilers

- Debris, particles, fibres and contaminant analysis in food and beverages

- Investigation of blistered coating on yacht caused by sodium chloride crystals

- Investigation of cracked plastic components such as ABS and polycarbonate cracking associated with cleaning and sterilising agent use.

- Stains on car roof liner fabric to find spherical mild steel particles from metal working

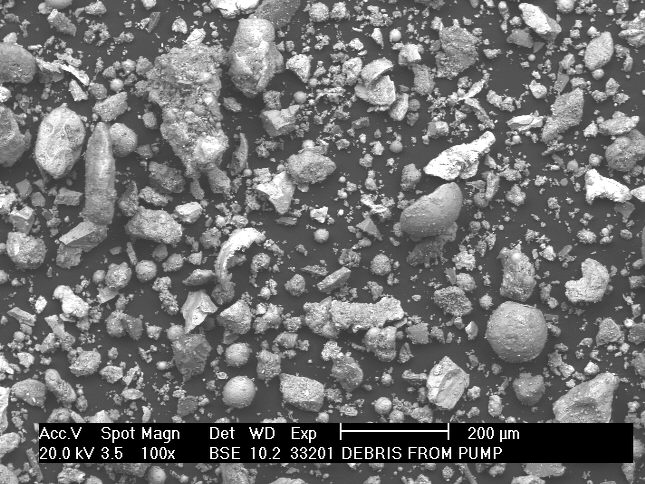

- Root cause of wear debris in train and ship water pump systems to determine wearing parts

- Detection of zinc whiskers in PCBs in data centres

- Investigation of residues from ship fire in a container

Range of Materials for Investigation by SEM / EDX:-

- Metals, Glass and Ceramics

- Semiconductors

- Plastics and polymers

- Powders, debris and Dust

- Composite Materials

- Fibres (Textile, fabric , man-made, natural, carbon fibres, glass fibres, kevlar)

Examples Applications / Case Studies

Image Magnification, Measurement and Resolution

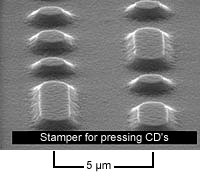

The image is of the surface of a metal stamper used to imprint the information onto a compact disc during manufacture.

The image is of the surface of a metal stamper used to imprint the information onto a compact disc during manufacture.

The image was taken at a magnification of X 40,000 on the SEM. The photograph illustrates the shape and structure of individual bits of information. The height, roughness and steepness of the sidewalls of the information are all critical to the manufacture of a good disc, as is the separation between adjacent tracks.

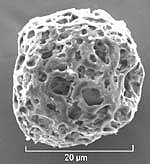

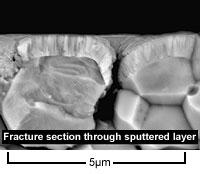

The second image is of a fracture section through a pellet made of tungsten powder that has been sintered and then sputter coated with an alloy of osmium and ruthenium.

The second image is of a fracture section through a pellet made of tungsten powder that has been sintered and then sputter coated with an alloy of osmium and ruthenium.

The output from both the secondary electron and backscatter detectors has been mixed together on the SEM to highlight the sputtered layer on the surface of the pellet. This enables accurate measurement of the thickness of the sputtered layer and shows the growth structure through the layer. The thickness of the layer was measured at 640 nm.

Analysis of Thin Films

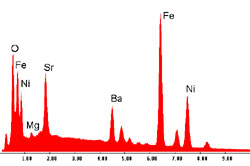

EDX analysis was carried out on a thin evaporated layer on top of a nickel / iron alloy.

EDX analysis was carried out on a thin evaporated layer on top of a nickel / iron alloy.

The layer contained a mixture of barium, strontium and oxygen, with a small amount of magnesium. The thickness of the layer was calculated to be ~ 38 nm.

If you would like to discuss your problem with us and find out how SEM / EDX can help you, please contact us and find out how we can help you today.

Our site expert on SEM / EDX Spectrometry is Keith Raper.

Application Notes