3D Printing Polymer Filament Quality by Pyrolysis GC-MS

As 3D printing expands into prototyping, production and education, the quality of plastic filament feedstock which include polymers like PLA, ABS, Nylon, PETG and ASA directly affects performance, reliability, and even user experience.

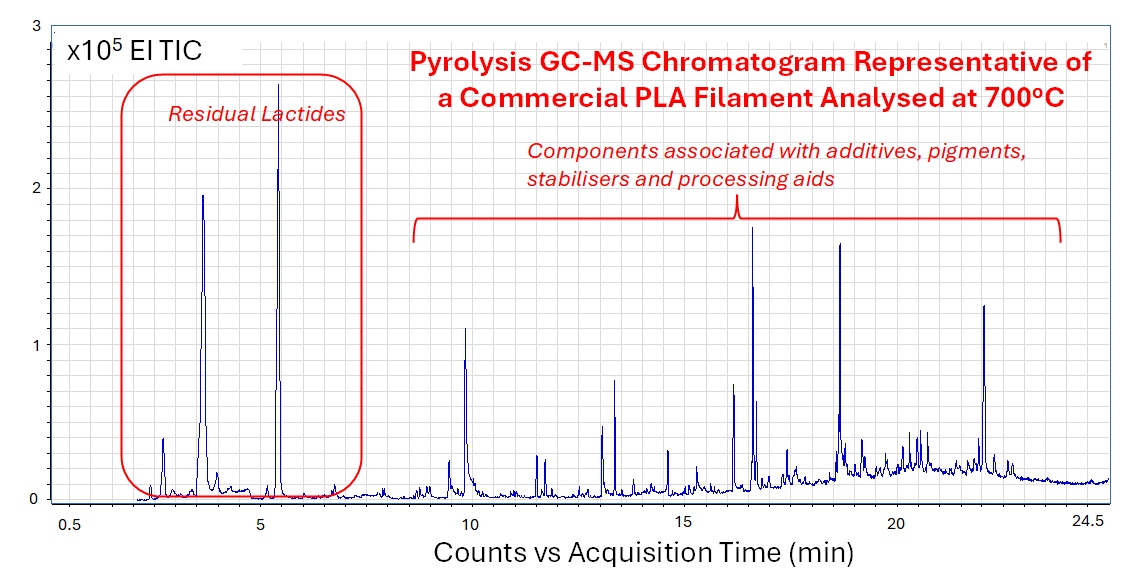

Pyrolysis GC-MS was used to investigate a selection of commercial PLA filaments, applying a two-stage heating profile to capture both low-temperature volatiles and high-temperature decomposition products.

Pyrolysis GC-MS was used to investigate a selection of commercial PLA filaments, applying a two-stage heating profile to capture both low-temperature volatiles and high-temperature decomposition products.

Analysis of results found:

- 200°C exploring thermal desorption revealed formulation differences between suppliers, including residual lactide, esters, fatty acids, and plasticisers such as di-n-octyl phthalate. Trace bromo-aldehydes and dye derivatives were also detected, which may contribute to odour or colour variations.

- 700°C pyrolysis showed the PLA backbone breakdown into lactide, cyclopentanone, hydrocarbons, and additional additives such as adipates, phthalates, stabilisers, and surfactant derivatives.

Pyrolysis GC-MS in 3D printing can be used to:

- Confirm the identity and consistency of supplied polymers.

- Highlight differences in additive packages that may influence print performance, stability, or long-term reliability.

- Support supplier comparisons and benchmarking, troubleshooting and quality assurance.