Interfaces, Additives and Coatings

In modern products and their manufacture there are many instances where two or more dissimilar materials need to be robustly joined together. Examples of such joints are:

- Paints or protective coatings for corrosion prevention or aesthetic reasons.

- Adhesives and joining technology to glue components together rather than using a mechanical fixing such as a rivet or nut and bolt.

- Holographic films which are complex stacks of printed and chemically etched metalised layers coved in an array of plastic films, adhesive layers and lacquers.

- Printed Packaging material used for foods etc. such as printed polypropylene (PP and BOPP), Polyethylene (LDPE and HDPE) and Polyethylene terephthalate (PET).

- Composite materials such as carbon fibre, Kevlar and glass fibre reinforced composites (CFRP and GFRP), ceramic matrix composites (CMC) and metal matrix composites (MMC) where load needs to be correctly transferred between the dissimilar materials of the reinforcement (often fibres) and matrix to help achieve the correct blend of materials properties such as strength, modulus, toughness and ease of manufacture.

- Metal brazing, weld and welding technology where load transfer is vital at the joint and heat affected zone (HAZ). In the alloy phases, created by the resultant local heat treatment, segregating elements can give weak boundary layers. Such imperfections can be highlighted by metallurgical cross-sectioning and examination by optical microcopy,SEM/EDX and AES (Auger). AES of fracture sections looking at a failure surface can show the faults clearly too as the segregating elements and phases will lie thinly on the fracture surface

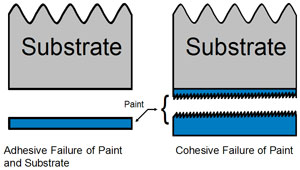

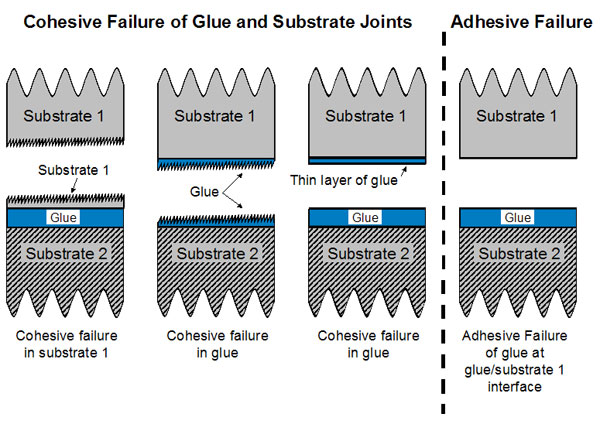

The strength and chemistry of the interface where materials meet is critical to the robustness and longevity of the joint. When joints fail they can fail cohesively or adhesively:

- Adhesive failure is failure at the interface where the substrate and coating / glue meet.

- Cohesive failure is failure either side of the interface, even marginally into the bulk of the substrate or coating / glue.

- A joint is considered poor if it fails adhesively at the interface as the joints are normally designed to be stronger than the material substrates.

Figure 1. Cohesive and Adhesive Failure of Paint Coating Systems

Figure 2. Cohesive and Adhesive Failure Applied to a Glued Butt Joint

The interface properties can be affected by the presence of weak boundary layers (WBLs) from:

- Contaminants from poor cleaning or substrate surface preparation processes prior to coating.

- Poor mechanical keying of coating to substrate or poor choice of the 2 materials so they do not interact chemically leaving a weak joint.

- Surface segregation of low molecular polymers due to poor resin and hardener mixing and incomplete reaction.

- Surface segregation of mold release agents (link to mold release) or plasticisers such as silicones from the substrate or coating.

- Inappropriate or incorrect use of Adhesion Promoters or sizes for composites.

Analysis to determine exactly what is on a failure surface is critical to determining why a joint fails. Determination of the Locus of Failure and the nature of any weak boundary layers is carried out by surface analysis, either XPS or SIMS coupled with FTIR as a fingerprinting technique. The wealth of experience of the laboratory in these matters allows advice to then be given how to contain and ultimately eliminate the problem.

Application Notes

Pdf Doc numbers - 0