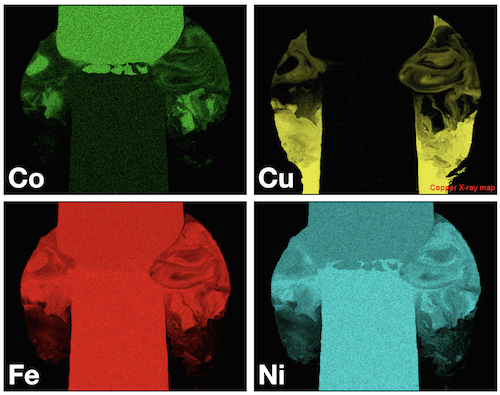

Metallographic Analysis Using SEM and Optical Microscopy

Metallographic analysis is suitable for the assessment of the physical, work hardened, chemical and grain structure of different metals, materials and coatings. The cross sectional techniques are often used to look for and examine buried defects, contaminants, flaws,and/or cracks to determine the root cause of failures.

The methods are also applicable for reverse engineering studies where the aim is understand how a component has been manufactured and processed for reject studies or competitor analysis.

LPD Lab Services Ltd has a wide array of the equipment and experience for the cutting, mounting and polishing of samples for metallographic analysis using optical microscopy or Scanning Electron Microscopy SEM.

LPD Lab Services Ltd has a wide array of the equipment and experience for the cutting, mounting and polishing of samples for metallographic analysis using optical microscopy or Scanning Electron Microscopy SEM.

- Samples can be cold or hot mounted. The auto-polishing unit allows up to 3 samples per session to be polished through five lapping and polishing stages. Cold setting resins are ideal for investigating fragile samples.

- For thin plated samples, an electroless nickel top coating can be applied prior to mounting and sectioning. (The nickel layer supports the plated layer during sectioning and gives an unambiguous layer thickness result).

- The Leitz metallurgical microscope has magnifications of 50, 100, 200 and 500 times, and is capable of conversion to transmission as well as reflection modes to assess metallurgical phases in etched microstructures.

- Microhardness indentation measurements can be made on specific areas of a microstructure, plating layers, coatings or surface treatment into the bulk to assess depth of mechanical property modification.

Metallurgical Preparation Equipment:

Metallurgical Preparation Equipment:

- Polyester and Epoxy cold resin kits

- Phenolic thermoset resin hot pressing kit

- Slow speed diamond saw

- Buehler Automated polishing/ preparation unit

- Polishing bench (2)

- Grinding bench

- Leitz metallurgical microscope (Calibrated graticule)

- Electroless nickel plating facilities

- Glass polishing equipment

- SEM facilities

Our site expert on Metallography preparation is Danie Els.

No documents matching criteria