Phenolic Foam Water Pipe Corrosion

Pinhole or pitting corrosion problems are common with copper pipes, steel water pipes and stainless steel steam pipes when insulated with phenolic foam and the pipework gets wet. These foam materials are used in open hot and cold water supplies and closed water systems such as heating or air conditioning systems because of the materials excellent thermal insulation properties.

Pinhole or pitting corrosion problems are common with copper pipes, steel water pipes and stainless steel steam pipes when insulated with phenolic foam and the pipework gets wet. These foam materials are used in open hot and cold water supplies and closed water systems such as heating or air conditioning systems because of the materials excellent thermal insulation properties.

Typically samples of failed pipe and foam insulation associated with the leak failure are provided for investigation. In the lab the foam insulation is soaked in water and the resulting solution is analysed for pH, to check if it is acidic, and for the presence of aggressive species by Ion Chromatography. The aim is to determine whether the foam creates acid environment that could attack the pipe if it gets wet and cause a leak.

Typically samples of failed pipe and foam insulation associated with the leak failure are provided for investigation. In the lab the foam insulation is soaked in water and the resulting solution is analysed for pH, to check if it is acidic, and for the presence of aggressive species by Ion Chromatography. The aim is to determine whether the foam creates acid environment that could attack the pipe if it gets wet and cause a leak.

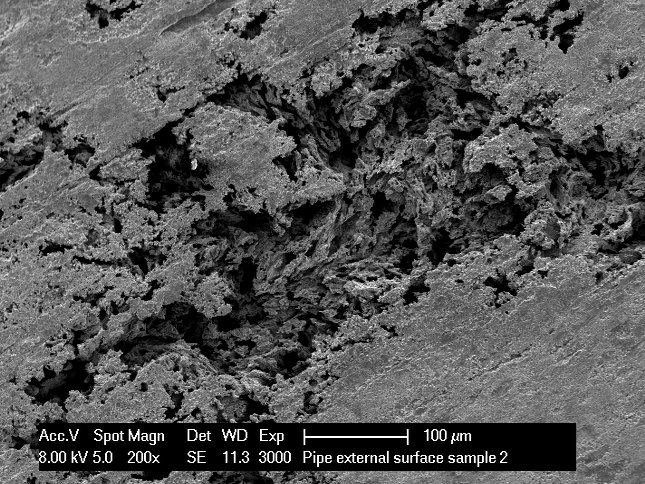

The key question in these corrosion problems is if the foam in service has got wet; where did the water come from. It could be water leaks, condensate from poor or a failed hermetic seal, weeping joints, poor repair or remedial maintenance work for example, all of which can be investigated in the laboratory by optical microscopy, SEM / EDX, IC and ICP-MS including looking at on-site water samples.

The other important factor is whether the pipe failed from inside, which may not due to foam but for other reasons such as flux residues, stagnant water or Microbiologically Induced Corrosion MIC, or outside which could be due to acid leached from wet foam. The pipe and insulation corrosion products are inspected inside and outside looking for the failure site or extent and composition of the corrosion.

The results are presented in an understandable manner, how the failure occurred trying to split the initial cause away from consequential damage, which is inevitable in water systems when the water is under pressure or there is a head of water. Any questions arising from the work are answered based on the work carried out in order to provide the best understanding of the problem and possible solutions or preventable measures.