Pyrolysis GC-MS

Introduction to Pyrolysis GC-MS

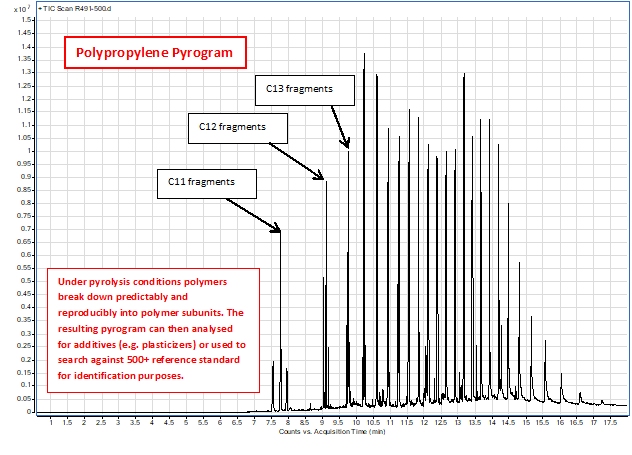

In Pyrolysis GC-MS, pyrolysis breaks apart large complex molecules into smaller more analytically useful fragments by the application of heat in the absence of oxygen. The pyrolate is then directly injected into the GC-MS simplifying sample preparation for identification against established databases derived for polymers and other organic molecules without the need for the analyte to be volatile unlike Headspace GC-MS, Thermal Desorption GC or the extra complication of solubility and interaction with organic solvents used in direct injection GC-MS. Without Pyrolysis some organic materials with large molecules like rubbers and polymers are unsuitable for GC-MS analysis without lengthy extractions or derivatisations.

Materials and Chemical Applications of Pyrolysis GC-MS

- Plant cellulose

- Paint and Coatings

- Adhesives

- Tapes caulking

- Food packaging

- Rubber

- Plastics

- Paper

- Ink

- 3D printed polymer filament quality.

- Household and consumer products.

- Assessment of thermal decomposition and breakdown temperatures and organic products.

- Analysis of organic volatile and mobile species and residues.

- Unknown organic residue identifcation and type matching.

Pyrolysis GC or GC-MS allows direct comparison of complex polymers, rubbers and organic compounds to look for changes in composition and potential mechanisms of failure.

Typical Example Applications of Pyrolysis GC-MS

Typical Example Applications of Pyrolysis GC-MS

- Identification of rubber types despite complex crosslinking and analysis of potential changes in additives.

- Analysis of plating solutions for trace organics.

- Identification of unknown natural organic substance on steel stock following transport thought to have leached from transport crates. Samples were initially analysed for polymer type identification by FTIR and then for identification of solvated compounds by GC-MS.

- Analysis of deposits on the surface of rubber gaskets.

- Analysis of dust and staining on different surfaces. Dust analysis in general is difficult as most components are not volatile so only FTIR can be applied and the specific conclusions can be limited. Dust analysis by GC-MS is more definitive and informative plus less subjective.

- Ranking of different candidate materials in complex rubber and elastomer degradation stability studies following exposure to model or real chemical environments. Assessments can be made on the extent of damage and the actual reaction products determined.

- Extraction and analysis of the organic components from oily residue on an air filter on fire damaged machinery. Pyrolysis GC-MS is a recognised and established forensic method of analysis of fire debris.

- Screening of phthalates in PVC components for RoHS compliance.

- Analysis of thermal degradation pathways in aerospace composites.

- Reactive gas pyrolysis for improved identification of additives and polar degradation products.

- Identification of residues on electronics linked to polymer breakdown.

- EGA profiles of flame-retardant systems to study efficiency and release behaviour.

Pyroliser Instrumentation and Capabilities

- IEC 62321-8 Phthalate Screening is a rapid and reliable screening of restricted phthalates in plastics for RoHS and REACH compliance.

- Evolved Gas Analysis EGA involves continuous heating to monitor volatile compounds released and degradation temperatures, linking analysis to other techniques including TGA.

- Reactive Gas Pyrolysis introduces specific gases (e.g. mixed inert or reactive and oxidising gases) during pyrolysis enhancing compound identification, permitting analysis under more realistic testing conditions and providing extra diagnostic power.

- On-Column Derivatisation provides improved identification of polar or labile compounds such as acids, alcohols and amines.

- High-Precision Multi-Step Pyrolysis is controlled sequential heating enabling detailed breakdown profiling of layered or blended materials.

- Broad Sample Compatibility can be assessed for solids, powders, films, fibres, liquids, adhesives, and surface residues can be analysed with minimal preparation.

- Thermal Desorption TD–GC–MS is possible on the CDS 6200 and is compatible with Markes and PerkinElmer 3½″ × ¼″ OD. tubes. It is ideal for VOC/SVOC emissions, outgassing and microchamber studies, and a powerful complement to Py-GC-MS and EGA.

- Direct transfer to GC-MS injection port or via trap for concentration measurements of the sample.

- Samples can be heated controlled from room temperature to to 1400degC with a 1degC resolution to allow large range of materials to be analysed at specific temperatures. This could be compared directly to TGA transition points to explain weight loss at a molecular level. This extends the thermal desorption injection system capabilities beyond 200degC and 400degC.

- Thermal trap can be used for direct analysis of contaminated air samples collected on Tenax tubes.

- Analysis of liquids, solids, polymers and ceramics where sample sizes 0.1-1.0g

- Sensitivity can be as low as ppb.