Paint, Adhesive, Sealant and Gasket Filler Fingerprinting

A combined physical and chemical analysis approach is a very powerful fingerprinting method of determining painting, adhesive, sealant and gasket history.

A combined physical and chemical analysis approach is a very powerful fingerprinting method of determining painting, adhesive, sealant and gasket history.

Paints are frequently used in products for corrosion and degradation protection or aesthetic purposes. Rubber and plastic seals, gaskets and sealant materials are used in production plant and commercial products too.

Both seals and paints contain inorganic particles called fillers for the following typical uses:-

- Extenders to reduce the amount of organic compounds required.

- Generate the better corrosion and degradation protective properties via increased diffusion path lengths for aggressive chemicals.

- Protection against UV or other radiation induced depolymerisation.

- Generate the required mechanical properties.

- Simple colourants or reflectivity for aesthetic purposes.

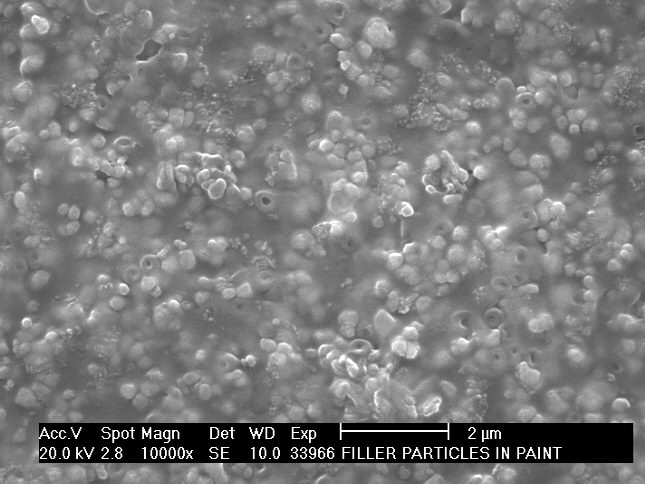

The mixture of filler materials are characteristic of the specific coating or seal material and act as an ideal fingerprint back to the manufacturer and sometimes even the production batch. Combinations of Semi-quantitative XRF, Optical Microscopy, SEM/EDX and Image Analysis, can provide this fingerprinting history. XRF provides an average bulk composition and the optical microscopy and SEM/EDX together provide the fine detail, perhaps in combination with particle counting techniques and image analysis. They generate additional information on characteristic volume fractions of specific compounds and the particle shapes and sizes.

This fingerprint information can be used to discover the source of microscopic contaminants such as worn out or shedding gaskets via a type matching exercise or even if paint formulations are badly mixed giving poor functional properties for example.

The organic binder, curing and polymer systems can be determined by a fingerprinting techniques called FTIR and GC-MS coupled with the laboratory's experience in typical formulations of paint, coating and adhesive systems.